Description

FEATURES & BENEFITS

• Rust-Resistant Hardware

• Smooth and sealed coating on the top and bottom of the cover eliminates load contamination of exposed fibers

• Stronger and more durable than others in the market

• AAR Approved

• Meets all AAR requirements as stated in S2037 for Trough Cover and S2039 for Batten Bars

• Interchangeable with current fiberglass market design

• Superior gasket adhesive creates strong bond

RELIABLE PROTECTION AND STRENGTH

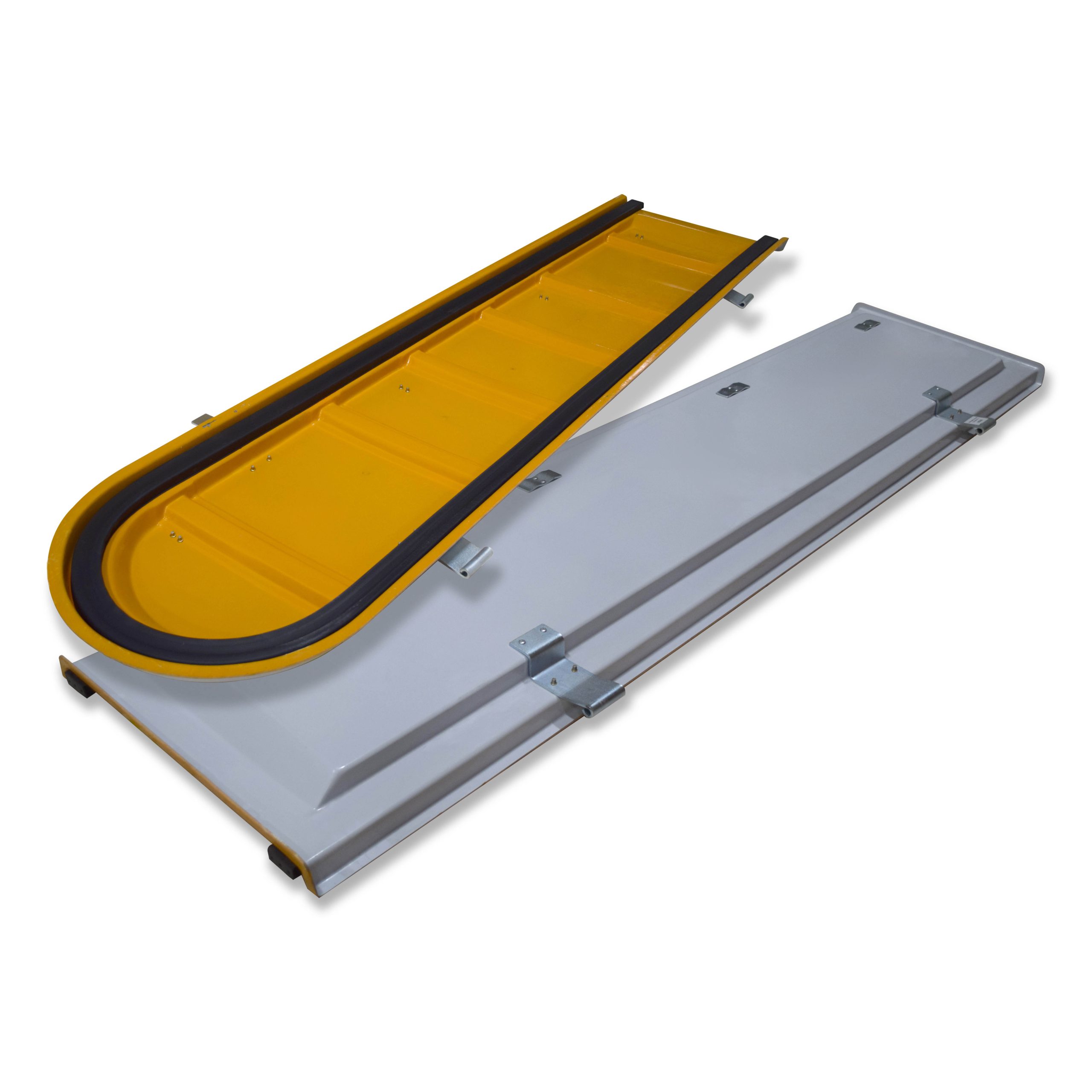

Engineered for durability and minimal maintenance, A. Stucki’s Trough Hatch Cover ensures prolonged service life. The interchangeable design (compatible with ATP) allows for easy installation and works seamlessly with existing equipment. A smooth finish eliminates fibrous contamination and simplifies cleaning while a stronger gasket adhesive ensures proper sealing with each loading cycle.

STATE-OF-THE-ART CONSTRUCTION

Using state-of-the-art molding technology with the strongest fiberglass available as well as multiple grades of rust-resistant hardware, long-lasting performance is guaranteed.

MATERIAL: FIBERGLASS

• Light Resin Transfer Molding (LRTM) technology.

• UV-resistant gel coat surface.

• Smooth topside and underside finish.

• Highest strength fiberglass in the rail industry.

SEALING

• Hollow chamber trough gasket allows for maximum sealing coverage.

• Superior adhesive prevents the gasket from peeling off of the cover.

LOADING

• Stainless steel or galvanized steel bumpers available in different heights to accommodate for various roof heights and designs

DURABILITY

• Fiberglass covers promise a long life of superior strength and corrosion resistance.

• Resilience to environmental factors eliminates durability concerns associated with polyethylene-coated, aluminum covers.

COMMODITIES

• Grain, soybean meal, malt/barley, salt, potash, corn gluten meal, lime, fertilizer, soda ash, bentonite/clay, and dried distilled grain (DDG).

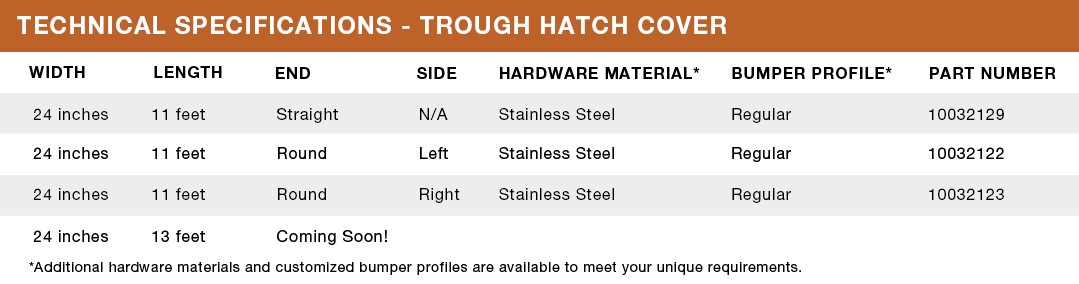

Looking to get started?

Click here to check out the information needed on our Trough Hatch Cover Request Form.